Chemical indicator inks market to accrue impressive remuneration from printing processes over 2017-2024, launch of innovative products to augment the global industry size

Publisher : Fractovia | Published Date : 2018-01-19Request Sample

The preeminent cause for robust and steady expansion of chemical indicator inks market size, in the recent times, could be attributed to the fact that there has been an overwhelming uptick in environmental regulations being prescribed by various nations to restrict the volatile organic compounds’ emissions. These regulations, as a consequence, have compelled the major chemical indicator inks industry participants to manufacture environment-friendly composition of inks by deploying water-based formulations, a trend that has favorably impacted the growth prospects of this business sphere. Furthermore, the overall chemical indicator inks market space has been witnessing improved profitability scope from the rising demand for disinfectants and sterilization instruments that are chiefly utilized in surgical procedures to prevent hospital-associated infections across the globe. Regarded as one of the most underrated vertical of bulk and specialty chemicals industry, the global chemical indicator inks market, owing to the emergence of eco-friendly solvents and enhanced technology, is forecast to expand at an impressive CAGR of close to 7 percent over 2017-2024.

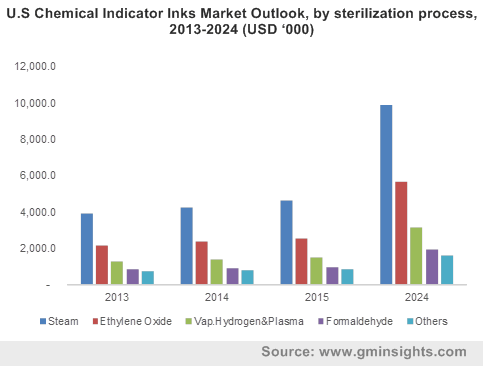

U.S Chemical Indicator Inks Market size, by sterilization process, 2013-2024 (USD ‘000)

The criticality of printing processes in chemical indicator inks industry

While elaborating further upon the growth potential of the overall chemical indicator inks market, it is rather imperative to take note of the significance and contribution of printing processes in the rapid expansion of this business space. The major products of chemical indicator inks industry, such as solvents, colorants, additives, and resins, are extensively used by these printing processes which include flexographic printing, screen printing, and rotogravure printing. Out of these printing processes, flexographic printing, in the last few years, has apparently cropped up as the most widely used process across a clutch of end-user verticals, given that it can be utilized in a wide variety of substrates including plastics and paper. The rising popularity of flexographic printing, which is projected to progress at over 9 percent CAGR in the next seven years, has proved to be quite beneficial for the overall chemical indicator inks market size augmentation.

Meanwhile, the rising preference for flexographic printing can be interpreted by taking into account the fact that this process has been increasingly proved to be more fluidic and cost-effective than rest of the processes. Furthermore, a host of prominent chemical indicator inks manufacturers have been directing their financial might and domain expertise to introduce innovative printing inks that would enlarge the chemical indicator inks market scope. One of the UK’s major chemical indicator inks firm, Ultrachem, for instance, has recently launched the UltraFlex UV Intense Flexo Ink series which has been termed as ideal for indirect food packaging and printing on the reverse side of cartons, wrap-arounds, pouches, and self-adhesive labels. The latest range of inks is said to possess the ability to meet challenges of the modern-day flexographic printing process, for these inks are reportedly produced on mono pigment based material that allows for maximum color strength, exceptional viscosity, adhesion, and gloss. Needless to mention, the advent of such promising products would invariably boost the growth prospects of the global chemical indicator inks market.

Concurrently, owing to the marked increase that is being observed in the commercialization of bio-based inks for food and beverages packaging has further embellished the expansion of chemical indicator inks industry size. These chemical indicator inks have apparently found massive applications in food and beverages industry, especially in canned foods vertical, such as to provide specific information pertaining to the completion of sterilization based on a diverse range of sterilant, as it prevents excessive food heating. To underline the growing contribution of these inks to the overall chemical indicator inks industry, a notable instance needs mention. The US-based specialty inks innovator for cans, Chromatic Technologies Inc (CTI) has recently unveiled a high-pressure indicator ink which is said to visually verify the food package that has been put through an advanced processing system to kill bacteria in the food. The CTI ink is water-based and UV-cured which appears clear when printed on food can lids, however, turns red to blue to confirm the process of sterilization. It goes without saying that the launch of such cutting-edge products would bring about a paradigm shift in the global chemical indicator inks market, which is slated to surpass a revenue portfolio in excess of USD 78 million by 2024.