Digital sorter market to accumulate substantial remuneration from food applications, global industry valuation to cross USD 3 billion by 2024

Publisher : Fractovia | Published Date : 2018-10-30Request Sample

Increase in the preference for automated manufacturing processes has propelled the digital sorter market, with food, mining and recycling businesses focused on establishing more efficient and speedy processing lines. The advent of sophisticated programming technology, along with the lowered costs and accuracy of automation systems have helped the penetration of sorting machines within distinct application areas. Whether it be the separation of waste materials on a conveyor belt in a recycling plant or sorting quality fresh produce in a food processing facility, the digital sorter industry has enabled the optimization of overall costs. Prominently, the ability to assist in monitoring and controlling the quality of food items during the processing and packaging stages has immensely benefitted the global digital sorter market, which garnered revenues of more than USD 1.5 billion in 2017.

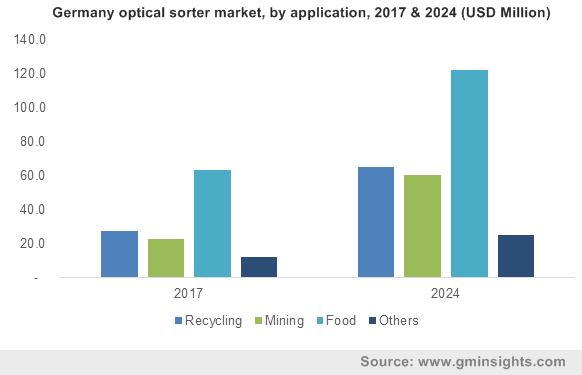

Germany digital sorter market, by application, 2017 & 2024 (USD Million)

Worldwide, government agencies and international organizations have introduced a number of regulations and guidelines for the processed food segment and supply of fresh produce. Consequently, businesses have been adopting advanced technologies for complying with stringent quality standards, ushering in tremendous opportunities for the digital sorter market players. Food sorting technology helps to lessen the risk of contamination from foreign materials and aflatoxins, proving to be an ideal investment by manufacturers to raise food safety on processing lines. According to certain reports, seeds, nuts and nuts products contributed the highest to the product recalls in Europe’s food sector in 2017, with fruit & vegetables and fish products following suit. Presenting a positive argument for the digital sorter industry, 24% of these food product recalls had resulted from bacterial contamination, 20% from aflatoxins and 13% from unauthorized ingredients.

Digital sorters offer the capability to detect and remove foreign material, undesirable rot, blemishes, greening defects, among other issues, making sure the customer is supplied with safer, better quality final product and with improved yield. The exponentially growing population base and the shifting trends in lifestyle have pushed the demand for processed food products higher, expanding the global food supply chain. With productivity, efficiency and economic challenges rising for the food segment, the digital sorter industry is essential for enhancing the output and to manage food ingredient quality at packaged food processing units. In 2015, the worldwide fruit and vegetable processing industry had recorded earnings of over USD 269.96 billion, indicating the extensive growth potential for the digital sorter market from the food segment.

By 2050, the global population could reach anywhere near 9.7 billion, as per estimates, while the disposable income in developing countries will also rise accordingly over the time frame. Depending on the population increase, the demand for food is anticipated to grow at rate between 59% to 98% by 2050 and industries will need to incorporate more automation technologies in their processes. The digital sorter market will be proliferated by the installation of advanced food sorting systems in most of the food companies during that time. Example of such systems are the advanced machines offered by a company named TOMRA Sorting Solutions, for the fresh and the processed food segments. TOMRA’s machines are able to inspect over a million product pieces every hour, which allow the manufacturer to recover 5% to 10% of the costs through improved utilization and higher yields as compared to manual labor.

Speaking further on the available industry leading sorting systems, Bühler has been providing companies with digital sorters for addressing the difficulties faced in maintaining food product quality and speed of operations. Comprising high resolution cameras and shape identifying technologies, its offerings represent innovative solutions existing in the digital sorter market that food producing companies can deploy for achieving superior precision in the sorting process. Bühler’s products are also suitable for operating in freezing temperatures at frozen food manufacturing plants, displaying the flexibility of the sorting machines.

With the presence of many such products developed for meeting specific requirements of food producers, the digital sorter market is expected to witness a 9% CAGR from 2018 to 2024 owing to accelerated demand for food products. In terms on the competitive hierarchy, the key industry participants include Bühler AG, Allgaier Werke GmbH, Newtec A/S, National Recovery Technologies LLC, Tomra Systems ASA, Satake Corporation, among several others.