APAC lithographic printing chemical market to accrue major returns by 2025, increasing development of eco-friendly products to characterize the industry growth

Publisher : Fractovia | Published Date : 2018-11-02Request Sample

The rising acceptance for lithographic printing process across the globe has been propelling lithographic printing chemical market share over the last few years. The lithographic printing process has been increasingly preferred for printing posters, books, greeting cards, brochures, advertising flyers, packaging, labels, newspapers, catalogs, and periodicals. Taking into account the expanding scope for this process, contributors in the lithographic printing chemical market have been implementing numerous business tactics lately to enhance their position in the business.

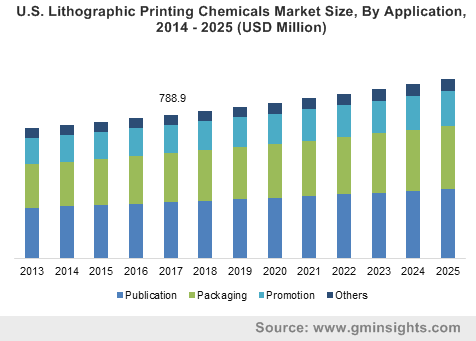

U.S. Lithographic Printing Chemicals Market Size, By Application, 2014 – 2025 (USD Million)

Some of the strategies implemented by the companies to proliferate the growth of lithographic printing chemical market and to enhance their marketplace have been discussed in the paragraphs below:

Printmaking is one of the unusual mediums that allows to develop affordable and desirable production of unique pieces. In regard to this, in recent years, the popularity of culture media has promoted the use of various printmaking process mainly lithographic printing that has been encouraging companies to develop advanced lithographic printing chemical. Recently, the research and innovation hub in nanoelectronics and digital technologies, imec and renowned lithographic equipment developer ASML collaborated to accelerate the adoption of lithography for high volume production.

In addition, they are looking forward to exploring the potential of next-generation lithography for printing smaller nanoscale devices. The joint research entails advanced usage of lithographic printing for manufacturing high resolution and small featured semiconductor devices. A JV such as the aforementioned would help encourage key players in the lithographic printing chemical industry to develop a wide range of products.

In the middle of 2018, Japanese lithographic printing chemical manufacturer, Toyo Ink Group announced its plan to expand its facility across Myanmar. With the development of the new plant, Toyo has been planning to strengthen its market competitiveness and business development capability across the APAC. This investment is likely to emerge beneficial for the contributors in the commercial printing and food packaging sectors in terms of getting access to high quality products in the local market.

In addition to this, taking into account the deployment of stringent regulatory norms related to the development of zero of low VOC products, Toyo has also decided to manufacture eco-friendly product ranges. The growing awareness among the food packaging industry about the safety and security of food packaging is likely to propel the demand for environmentally friendly printing inks.

The shifting trends toward the adoption of flexible and sustainable packaging have also had a positive impact on the development of lithographic printing chemical. The growing concerns about the adverse impact of non-degradable packaging on biodiversity is one of the major factors influencing the need for flexible packaging. In this regard, most of the leading lithographic printing chemical market contenders have been investing in the development of sustainable raw materials for flexible packaging. The development of sustainable and eco-friendly printing chemicals will thus help them target leading end-use domains of flexible packaging such as the pharmaceutical sector, medical research centers, and hotels.

The growth map of lithographic printing chemical market is also influenced by the regulatory landscape governing this business space. Numerous regional governments have been deploying supportive policies such as relaxation in import taxation and infrastructure enhancements to attract foreign investments. Such strategies will help countries strengthen its position as an investment destination for the players in lithographic printing chemical market.

The evolution of new technologies such as 3D printing and additive manufacturing has turned out to be rather beneficial for lithographic printing chemical market magnates. In line with the changing technological trends, printing chemical manufacturers have been evaluating the applicability of their products for attracting more customers. Administrative bodies are also expected to play a major role in the development of printing chemicals with the enforcement of supportive regulatory norms. The increasing importance for flexible packaging and commercial printing across myriad end-use sectors will generate lucrative opportunities for the lithographic printing chemical manufacturing companies. As per a report by Global Market Insights, Inc., lithographic printing chemical market will surpass a revenue collection of USD 17.5 billion by the end of 2025.