APAC Oil-Free Air Compressor Market to witness phenomenal proceeds over 2018-2024, with China as major growth avenue

Publisher : Fractovia | Published Date : 2017-05-12Request Sample

Atlas Copco’s latest range of VSD compressors is sending out waves of anticipation in oil-free air compressor market. Dubbed as ZR 90-160 VSD+, the Swedish giant’s most recent line of oil-free rotary screw air compressors, is claimed to offer 10% more output, with over 15% energy saving as compared to other compressors available in the oil-free air compressor industry. Endowed with such unique features and an extensive motor variants range of 160 kW, 145 kW, 132 kW, 110 kW, and 90 kW, this breakthrough product is likely to amass a huge popularity across myriad end-use industries like food & beverage, textile, automotive, and electronics sector. In addition, ZR 90-160 VSD+ also boasts of an extraordinary product design that includes two highly-efficient permanent magnet motors, an enhanced brand-new compressor element and a compact design that reportedly take 25% less floor space as compared to its counterparts. Considering all these axioms, this new water-cooled product may, in all plausibility, would set a new benchmark in oil-free air compressor industry.

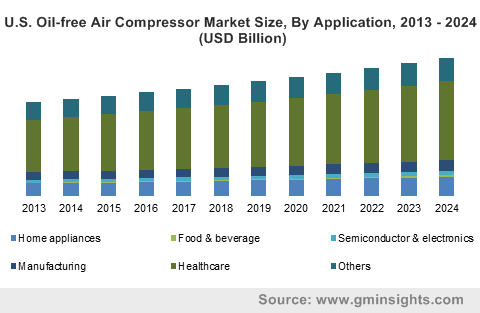

U.S. Oil-free Air Compressor Market Size, By Application, 2013 – 2024 (USD Billion)

Atlas Copco’s initiative also throws a light on the fierce competitive scenario of oil-free air compressor market and the unprecedented product developments that this vertical is presently characterized by. Citing yet another instance depicting the extent by which the market players are vying with one another to establish their stance in the dynamically intense share battle, Sullair, the U.S. based industry player has recently unveiled its latest OFD1550 oil-free portable air compressor at The Rental Show of 2018. As claimed by the official sources, this breakthrough product comes in response to the growing demand for sensitive compressed air, especially across verticals like pharmaceuticals, food & beverage, and electronics. In fact, dedicated products are required for back-up oil-free air and oil-free plant air. The OFD1550 range aptly fits into these criteria, providing a viable solution to the consumers in the changing merchandizing spectrum.

What is significant from these design permutations by renowned biggies is that the technological interventions aptly define oil-free air compressor market’s profitability landscape. In fact, the overall business space apparently has found a major driving force in the emerging trends of automation and robotics. The extensive penetration of industrial robotics across various applications has indeed acted a catalyst in the expansion of the oil-free air compressor industry, in terms of groundbreaking innovations. Speaking of the technological layout, rotary and reciprocating based compressors are two major technologies that are slated to gain substantial traction over the recent years. Reportedly, the reciprocating compressor technology in the U.S. oil-free air compressor market held a share of approximately 30% in 2017.

Having retained a position of supremacy by procuring almost 60% of the global share in 2017, APAC is deemed to hold its dominance in global oil-free air compressor industry over 2018-2024. The massive scope of the regional oil-free air compressor market mainly stems from the extensive regional manufacturing activities. China is touted as the chief revenue pocket for APAC with an anticipated CAGR of 4.5% over 2018-2024. As per reliable estimates, stationary compressors led the country’s oil-free air compressor market product landscape with a share of 80% in 2017.

It is important to mention that though oil-free compressors are gaining an edge with ongoing modernization, a slightly high-end initial investment compared to its contemporaries is claimed to be a stumbling block in the oil-free air compressor market growth. However, the ROI from incorporating these systems in the production process is huge, evident from the commendable energy efficiency and superior productivity achieved. Regular maintenance of air compressed systems is highly critical as it is prone to oil adulteration, whereas in case of oil-free air compressors, downstream filtration requirement is comparatively minimal, which by extension leads to energy saving. All in all, powered by the energy sustainability notion encompassing the manufacturing domain, oil-free air compressor market is slated to witness commendable proceeds over the ensuing years. In terms of revenue potential, the fraternity is estimated to surpass USD 14 billion by 2024.