Precision Gearbox Market to witness considerable growth via high demand in service robotics

Publisher : Fractovia | Published Date : 2017-03-01Request Sample

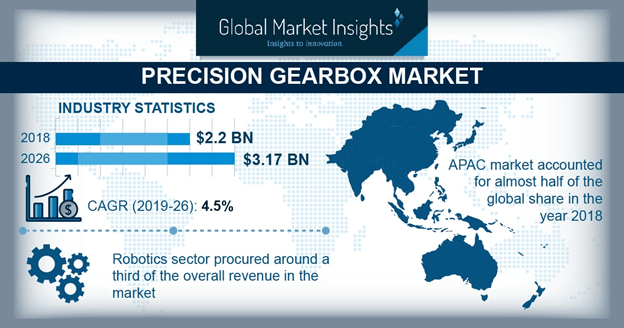

Advanced technology to improve energy efficiency will catapult the global Precision Gearbox Market. The fast-emerging field of industrial and service robotics will generate demand for these products in applications such as packaging, conveyor belts, bottling, and assembly lines. Manufacturers often implement features such as maintenance-free construction, high torque speed reduction, smooth running, and efficient design to fuel product demand. According to Global Market Insights, Inc., “Global Precision Gearbox Industry is anticipated to grow at a CAGR of 5.2% over 2016-2024.”

Precision gearbox market finds applications in the food & beverage, material handling, robotics, military, tobacco, and packaging sectors.

Germany Precision Gearbox Market size, by application, 2012-2024 (USD Million)

Global precision gearbox industry size in food, beverage, and tobacco applications was worth more than USD 170 million in 2015. The robotics application segment is expected to record a CAGR of 6.5% over 2016-2024, driven by the rising demand for prosthetic joints and limbs in service robots.

Rising requirement for automation and highly efficient machinery will fuel industry growth over 2016-2024. Precision gearbox market for automated material handling is expected to grow at a healthy rate over 2016-2024, owing to the increasing demand for high-tech equipment, improved infrastructure, and construction of better warehouses.

In terms of product, this industry is divided into parallel, right angle, and planetary. Right angle precision gearboxes are extremely flexible owing to the angular arrangement between the output shaft and the drive. Due to their increasing popularity and flexibility, they are widely used in applications with limited construction space, such as remodeling. Planetary precision gearbox market contributed to more than 70% of the total share in 2015 and is expected to grow steadily, owing to greater product volatility.

Parallel precision gearbox industry size was valued at more than USD 200 million in 2015. These products find uses in conveyor belts and similar material handling appliances.

Increasing requirements for innovation are prompting manufacturers to come up with small-sized, precise, highly accurate, and handy gears that find uses in processes such as packaging, bottling, conveyer belts, and fluid injection.

This industry is subject to standard regulations regarding energy consumption and product operation. The European Union (EU) has introduced revised regulations since January 2015 to improve energy efficiency by more than 25%. The U.S. has also outlined regulations in ANSI standard for the robotics sector. Increasing number of regulations governing this market will help maintain product standard, reduce energy consumption, and improve the overall efficiency.

Regional manufacturers have a considerably strong industry share owing to the cost-related benefits that they provide to consumers. However, companies such as SEW Eurodrive, Brevini, and Siemens already have a strongly established hold over the business. Their presence and the elevated R&D spending obstruct aspiring companies to get a foothold in the market.

The U.S. primarily led north America precision gearbox industry, contributing to more than 80% of the regional market share in 2015. The requirement of high accuracy with lesser costs will increase product demand over 2016-2024.

China precision gearbox market was worth USD 270 million in 2015, and is expected to witness healthy gains in the years to come. The nation’s efforts to manufacture high quality products using automation to reduce labor costs will support product demand.

A key tactic adopted by powerful industry players is to offer unique characteristics such as maintenance-free construction, extremely high efficiency, and speed-reducing devices, to increase brand value and identity. Techniques like 3D modeling help manufacturers design tailored products at a relatively low cost. The rising demands for customized products will thus fuel the precision gearbox market.

Energy-efficient systems are extremely vital to facilitate reduced overall investments and reduced energy consumption. Global precision gearbox industry share may be hampered by similar products such as direct drive systems, that are lightweight, less complex, highly efficient, and less expensive. However, the growing demand for automation in manufacturing and machine tools will propel market growth.