Recycled elastomers market to exhibit a double-digit CAGR over 2018-2025, rising demand for sustainable material from the automotive sector to expedite the industry growth

Publisher : Fractovia | Published Date : 2018-08-23Request Sample

The massive rise in the rate of recycling industrial products has been fueling recycled elastomers market share since the last few years. Presently, elastomers find profound applications in many end-use commodities ranging from ordinary rubber bands to industrial products. The large-scale deployment of elastomers across the medical, automotive, aerospace, sports utilities, and infrastructural sectors has been generating a significant amount of scrap annually. Considering the adverse impact of elastomeric scrap on the environment, many regulatory bodies and regional governments have been encouraging the deployment of recycled elastomers for manufacturing end-use products, thereby propelling recycled elastomers industry share.

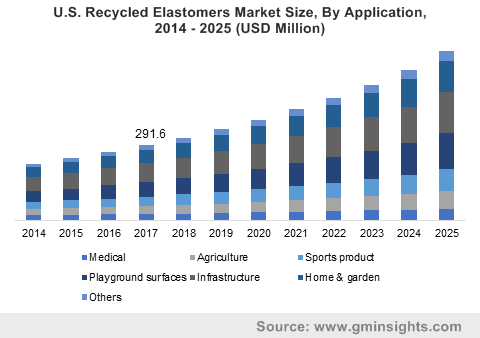

U.S. Recycled Elastomers Market Size, By Application, 2014 – 2025 (USD Million)

In order to comply with the regulatory policies, recycled elastomers industry giants have been looking forward to developing effective elastomer recycling methods. In accordance, these companies have been working in research and development projects that will considerably stimulate the recycled elastomers market size over the years ahead.

Since the last few years, the demand for tires has observed a major upsurge, pertaining to the ever growing vehicle requirement. The rise in per capita income along with changing lifestyle patterns have been fueling the sale of automobiles. Considering the upcoming impact of the rise in tire scraps, leading tire manufacturers have been putting more emphasis on the use of recycled and renewable materials in tires. In line with the extensive use of recycled materials in tires, leading automotive and aerospace tire manufacturers are certain to accrue a substantial share of recycled elastomers market.

Speaking along the same lines, it is prudent to mention that most of the companies have been formulating sustainability policies to increase the dependency on renewable materials. In addition, a few companies have been investing in the development of effective recycling technologies owing to the low recovery rate as compared to the use of sustainable materials. The visionary approach of tire manufacturers will lead to a fierce competition among the giants in recycled elastomers industry over the years ahead. Validating the aforementioned fact, a few months before, renowned tire manufacturer, Michelin planned to produce tires with 100% recycled material by the end of 2048. As of now, it uses 26% sustainable materials such as natural rubber, limonene, and sunflower oil in the development of recycled tires.

Taking into account the environmental and revenue benefits of recycled materials, Michelin has also decided to increase the content of sustainable materials in recycled tires to 80% with the deployment of advanced recycling technology. In accordance, Michelin has been spending nearly 700 million Euros annually on research and development activities. In 2012, the firm launched the Biobutterfly program to encourage researchers to develop synthetic elastomers from bio-based products. In addition, recently, it also established a research and development facility in India to conduct in-depth research related to the integration of renewable and recycled materials in tires. Such initiatives would help contributors in recycled elastomers market to generate considerable revenue over the years ahead.

In response to the exponential growth in packaging and automotive markets along with strict regulatory norms mandating the use of recycled elastomers in various end-use products, the giants in recycled elastomers industry have been investing in capacity expansions and regional facility extensions. With such strategies, these companies have been procuring commendable monetary benefits, gaining an edge over their competitors. For instance, leading manufacturer of thermoplastic elastomers, Polymax Thermoplastic Elastomers L.L.C. has decided to increase its annual production capacity by nearly 8 million pounds. The company built a new facility to expand the manufacturing capacity of thermoplastic elastomers comprising styrene-butadiene-styrene rubber, hydrogenated rubber, and thermoplastic polyolefin. Incidentally, estimates claim that recycled elastomers market size from styrene butadiene rubber will grow at a CAGR of more than 13% over 2018-2025. Considering that the material would be in extensive demand in the years ahead, it is rather overt that the segment would prove to be a lucrative growth avenue for recycled elastomers industry.

The significant investments in the development of sustainable products along with business expansion strategies will unlock new opportunities for the giants in recycled elastomers market. Powered by the supportive regulatory policies related to the use of recycled and renewable materials, recycled elastomers industry contenders are likely to gain profits with the adoption of numerous business strategies. The shifting focus of product manufacturers toward the use of recycled materials will have a remarkable influence on overall recycled elastomers market which will generate a revenue of over USD 6 billion by the end of 2025.