How will growing automotive industry shape sandblasting machines market?

Publisher : Fractovia | Latest Update: 2019-08-09 | Published Date : 2018-07-04Request Sample

Expanding construction industry along with penetration of robotics & automation across various industry verticals including marine and automotive are expected to drive sandblasting machines market size over 2019-2025.

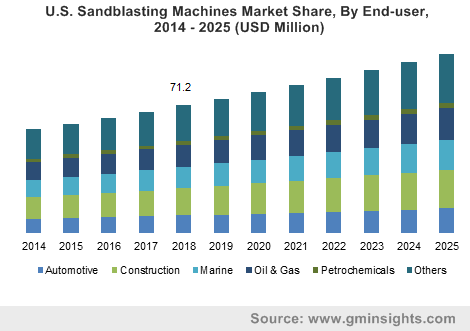

U.S. Sandblasting Machines Market Share, By End-user, 2014 – 2025 (USD Million)

Automated sandblasting is extensively used in repair and construction activities, including construction of bridges, residential & commercial buildings, architectural structures etc., for cleaning and surface finishing applications. Surge in robotics equipment demand in construction industry will further create need for these products. Moreover, rising residential building demand in emerging economies across the world is likely to drive the product demand over the forecast timeline.

How will growing automotive industry provide impetus to sandblasting machines market?

Automotive refurbishment industry provides a huge opportunity for the sandblasting machines market growth due to the product’s application in repair and repainting of tanks, vintage cars, railway carriage trolleys, etc.

These machines are used in the pre-treatment process in electroplating applications, polishing activities and surface finishing in vehicle manufacturing. Automotive industry will generate significant product demand in the coming years. Increase in the number of vehicle sales is also likely to propel sandblasting machines market expansion.

How will sandblasting machines market profit from its end-user industries?

Based on end-user industry verticals, the sandblasting machines market is categorized into marine, petrochemicals, construction, oil & gas, automotive, etc. Sandblasting machines are majorly used for surface cleaning in boat hull structures. Oil and gas sector is estimated to witness growth of over 5% over the forecast timeline. Furthermore, marine industry is predicted to garner significant proportion of sandblasting machines market share due to growing new ship construction as well as maintenance & repairs of existing ships.

Will Asia Pacific emerge to be a region offering substantial gains to augment sandblasting machines market outlook?

With rising construction activities and industrial manufacturing, Asia Pacific region is estimated to hold a share of 35% in the sandblasting machines market over the forecast timeline. Moreover, growing automotive industry in major countries including India, Japan and China will generate significant product demand and hence expand the sandblasting machines market trends.