Semi-Rigid Spray Polyurethane Foam Market to derive remarkable proceeds via wall segment over 2018-2024, adoption of eco-friendly materials and advanced technologies to characterize industry landscape

Publisher : Fractovia | Published Date : 2018-06-13Request Sample

The recent announcement of NCFI Polyurethanes, one of the foremost companies partaking in semi-rigid spray polyurethane foam market, to offer a new range of spray polyurethane foam underscores the efforts being put in by industry giants to manufacture eco-friendly products. Formulated with Honeywell's Solstice® Liquid Blowing Agent (LBA), the new low-global-warming-potential (low-GWP) material has been specifically produced for roofing applications and is part of NCFI’s commitment to lower its carbon footprint. Of late, it has been observed that the competitive spectrum of semi-rigid spray polyurethane foam industry has increasingly been influenced by mounting calls to transition from hydrofluorocarbon (HFC) to low-GWP products which has perpetually benefited the revenue share of this business space.

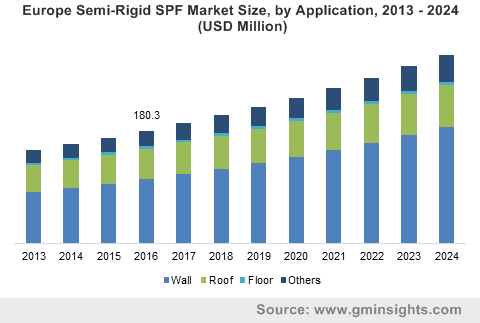

Europe Semi-Rigid SPF Market Size, by Application, 2013 – 2024 (USD Million)

Over the past decade, the phaseout of HFCs has been the primary concern of environmental regulatory authorities across the globe. In this regard, the latest offering of NCFI is being cited as revolutionary given that the firm has embarked upon transitioning its entire engineered building products range from HFC blowing agents to low-GWP products with the integration of Honeywell’s Solstice LBA. Based on ultra-low GWP hydrofluoro-olefin (HFO) technology, Solstice LBA has emerged as a crucial component in manufacturing polyurethane foam. Evidently, the increasing instances of semi-rigid spray polyurethane foam market players adopting environment-friendly ingredients to produce these materials would go a long way in augmenting the growth prospects of this business sphere.

Elaborating further, the demand for deploying polyurethane foam as insulation in exterior wall construction has been on the rise lately. It is rather imperative to take note of the fact that these materials provide superior air barrier facility, expand 100 times to its original volume, and improve water adsorption property by up to 40%. These excellent properties have invariably resulted in extensive usage of polyurethane foam as wall insulation across commercial and residential sectors. In fact, wall as an application segment of semi-rigid spray polyurethane foam industry apportioned close to 50% of the global share in the year 2017, claims a study undertaken by Global Market Insights, Inc.

To add to it, prominent firms operating in semi-rigid spray polyurethane foam market have directed their resources in developing enhanced spray polyurethane foam insulation which can be predominantly utilized in wall construction. Lapolla Industries, Inc. for instance, recently unveiled an all-new and improved open-cell spray polyurethane foam insulation, Foam-LOK 500. The latest material reportedly can be utilized to seal 2” x 6” stud wall construction in a single application and works by forming a completely sealed air barrier in wall cavities. Ideal for deploying in commercial and residential complexes of almost all kinds, the launch of products like Foam-LOK 500 is touted to significantly transform the growth fortunes of wall as an application segment of semi-rigid spray polyurethane foam market in the times to come.

While the commercialization scale of the semi-rigid spray polyurethane foam industry appears highly-promising, it deems fit to take note of the challenges that this business space might face in the near future. In this regard, one of the major restraining factors to have dampened the proliferation of product demand has been the volatility in the prices of crude oil which is the most essential raw material in manufacturing these chemicals. In addition to this, various health hazards that are caused by crude oil derived products have been posing considerable threats to the rapid product expansion in the recent times.

In order to address the aforementioned challenges, prominent semi-rigid spray polyurethane foam market players, of late, have focused on revamping their production units to swiftly adopt advanced technologies. For instance, the United States headquartered Rhino Lining Corporation has reportedly manufactured bio-based SPF products in the recent past.

Industry experts claim that the process of manufacturing environment-friendly and bio-based SPF products has been undergoing a drastic change with the integration of these high-grade technologies. This would eventually prove to be advantageous for the remuneration portfolio of semi-rigid spray polyurethane foam industry which is slated to surpass the billion-dollar frontier by 2024.