Textile Coatings Market to accumulate massive revenue via surging demand from the construction and transportation sectors over 2017-2024

Publisher : Fractovia | Published Date : 2017-09-15Request Sample

Covestro’s recent product launch demonstrates the company’s immense contribution toward textile coatings industry. Elaborating further, Covestro recently introduced a new kind of polyurethane raw material dubbed Baymedix®, that finds applications in wound dressing and healing processes. Deploying textile coatings to manufacture medical furniture coatings, bandages, surgical wear, and hospital bed linen has always remained at the center stage of the firm’s material development plans, the Baymedix launch being a pivotal instance of the same. Covestro had recently demonstrated the application of Baymedix® across waterborne textile coatings and non-latex cohesive bandages at the INDEXTM 17 trade fair held in Geneva in April 2017. Experts state that having witnessed the product’s exceptional performance, other companies are likely to follow suit and bring about innovations in their product line, which would undeniably propel textile coatings market size in the years ahead.

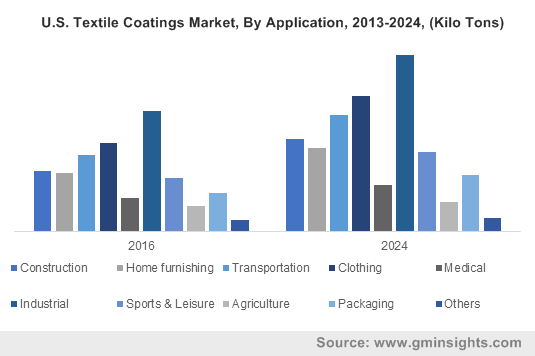

U.S. Textile Coatings Market, By Application, 2013-2024, (Kilo Tons)

An insight into the contribution of textile coatings market players

- In a key breakthrough witnessed across textile coatings market, Umbra Applied Technologies Group (UATG), a new entrant in the textile industry, has planned to introduce a new product line - Hygieia that has been touted to be the future of smart textiles. Foraying into the smart textile sector is certain to help the firm expand its presence across the smart technology business space in addition to the textile coatings industry.

- Another textile market giant – the Cordura Brand of Invista, has collaborated with DuPont Tate & Lyle Bio Products LLC to manufacture eco-friendly fabrics. The new durable fabric is likely to attract footwear, textile, and gear designers subject to the fact that the fabric constitutes high performing coatings and membranes. This collaboration is thus, likely to open new growth avenues for the prospective deal participants, in addition to bringing about a dynamic change in textile coatings market.

- Recently in June 2017, the nanotechnologists at Nanex – a privately held firm offering real time analysis and market data services, deployed nanotechnology to efficiently develop new waterproof coatings for textiles & leathers. Apparently, this new product helps the footwear and fabric manufacturers to produce water-resistant, durable, and self-cleaning products, devoid of materials that may harm the environment.

- A recent research study unearthed by a group of European researchers depicts the use of graphene to coat textiles and make them conductive. Apparently, this has been perfected by converting thermoplastic monofilament fabric fibers into conducting ones through a graphene coat. This breakthrough is expected to open a new platform for creating integrated electronic equipment that can be directed into the fabrics. This coating technology is bound to bring about a transformative trend in textile coatings market in the near future, state experts.

Textile coatings find myriad applications in the production of hygiene textiles, sports clothing, protective clothing, and barrier textile. Silicone based elastomeric coatings are extensively used to coat nylon fabrics, industrial textiles, fiberglass, and polyester clothes. Today, silicone based coatings have found widespread applications in textiles with their ability to offer protection against ultraviolet radiations, heat, mechanical stress, and fire. With their high insulating features, the products have become highly popular across welding blankets, insulation panels, and personal protective equipment (PPE) market, creating a massive spectrum of avenues for textile coatings industry.

Textile coatings are invariably used across the construction sector, subject to their anti-abrasion, fire retardation, and anti-bacterial benefits. Inadvertently, this goes to prove that the expansion of the construction sector would directly benefit textile coatings market growth. This fact especially holds true for the APAC textile coatings industry, given the extensive development of the construction sector in the continent. Estimates claim APAC to have accounted for over 50% of global textile coatings market share in 2016. With the expansion of the construction and transportation sectors across regions such as India and China, APAC textile coatings market is likely to depict a lucrative growth curve in the years ahead.

U.S. textile coatings market, on the other hand, is expected to be driven essentially by product innovations. The region has been depicting prominent growth in the clothing and home furnishings sectors, which would subsequently impel the profitability landscape of U.S. textile coatings market, slated to grow at a CAGR of 4.5% over 2017-2024.

The competitive hierarchy of textile coatings industry is remnant of renowned biggies such as Clariant AG, Huntsman International LLC, Covestro AG, Omnova Solutions Incorporation, Royal DSM AG, BASF SE, and Lubrizol Corporation. It would be prudent to mention that the aforementioned firms are expected to make notable contributions toward textile coatings market in the forthcoming years and beyond, that would substantially impel the business landscape. Endowed with widespread application and technology spectrums, textile coatings market size is expected to be pegged at USD 7.5 billion by 2024.