Thermoplastic Elastomers (TPE) market outlook: North America to prominently drive the global revenue

Publisher : Fractovia | Published Date : 2017-02-08Request Sample

The surging demand for waste reduction, recyclability, and low weight vehicles will stimulate Thermoplastic Elastomers Market significantly over the coming six years. TPE based products are prominently used in construction, medical, automobile, and footwear industries, which will fuel the global TPE industry trends significantly. According to Global Market Insights, Inc., “Worldwide (TPE) thermoplastic elastomers market share is anticipated to record a CAGR of more than 6% over the coming six years. The government is trying to reduce carbon and GHG emissions by applying stringent rules and regulations on plastic usage, which will, in turn, enhance TPE industry outlook.

Asia Pacific thermoplastic elastomers market was worth over USD 4 billion in 2015 and is anticipated to witness significant growth over the coming years, driven by the escalating number of automotive manufacturing plants. The plenty availability of skilled labor as well as ample raw material resources will considerably influence the TPE market share. India, China, and Japan will be the major revenue pockets of the APAC, with China having had the majority of market share in 2015.

Germany Thermoplastic Elastomers Market size, by product, 2013-2024 (USD Million)

Europe thermoplastic Elastomers market accounted for 20% of the global revenue in 2015. The TPE material has low material density and high strength as compared to metals and is thus preferred in automobiles to achieve reduced weight and high fuel efficiency. In addition, the introduction of new alternative materials such as ethylene propylene diene monomer (EPDM) and ethylene propylene rubber (EPR) will also fuel Europe TPE market size over 2016-2023.

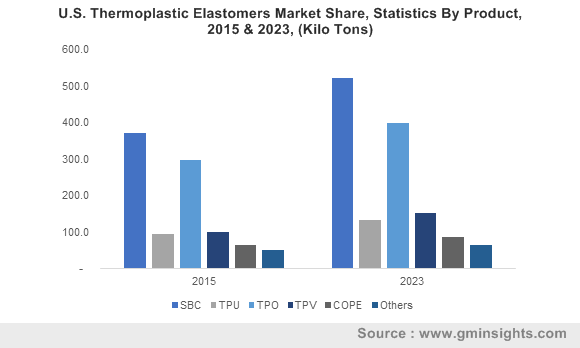

North America TPE industry size accounted for more than 27% of the worldwide market in 2015 and will grow noticeably over the coming period, owing to the favorable EPA norms regarding the usage of eco-friendly products along with its growing requirement for vehicle manufacturing. U.S. will contribute primarily towards the thermoplastic elastomers market regional growth.

The growing demand for electronic goods as well as rise in construction expenditure will fuel MEA thermoplastic elastomers market share, which will exhibit dynamic growth rate of 4.9% over the coming six years. The easy availability of raw materials will further drive the MEA TPE industry share notably.

Styrenic Block Copolymers, Thermoplastic Polyurethanes, Thermoplastic Polyolefins, Copolyester Elastomers, and Thermoplastic Vulcanizates are some of the vibrant products in the TPE market. Thermoplastic polyurethane (TPU) market will grow noticeably by registering CAGR of more than 5% over the period of 2016 to 2023, primarily driven by its escalating demand across construction applications, due to its superior thermal and acoustic properties. Furthermore, rising demand for TPE across the automobile industry and strict regulations for energy efficient buildings will generate lucrative opportunities for thermoplastic elastomers industry.

Copolyster elastomers (COPE) will calculate a revenue of over 1 billion by 2024, owing to its surging need across the electrical and electronics based applications. Its characteristics such as resilience, versatility, and high durability will propel the industry growth notably over the coming timeline. Styrenic Block Copolymers (SBC) market dominated the product landscape by witnessing a revenue of USD 6.22 billion in 2015 and will observe high demand over the coming years, owing to its mounting requirement for the applications such as packaging and medical equipment.

Major market giants accounted for more than 40% of the global TPE market share in 2015. Mergers & acquisitions, new product development, and capacity expansions are some of the key growth strategies adopted by the industry participants to increase their business. The leading players include Dow Chemical Company, Kraton Polymers, BASF, LyondellBasell, China Petroleum & Chemical (Sinopec), Covestro, EMS group, Arkema, and Nippon Polyurethane Industry Co., Ltd.