UV adhesives market to register itself in the billion-dollar business space by 2024, widespread product demand from the medical device manufacturing and electronics sectors to drive the industry growth

Publisher : Fractovia | Published Date : 2018-04-20Request Sample

The expanding manufacturing sector can be officially credited as being a major trigger for UV adhesives market growth, subject to the demand for strong bond strength and rapid curing time in manufacturing procedures. UV adhesives are known to cure in a very short time span and are preferred for their quality of being able to bond dissimilar materials or substrates. Additionally, they offer the advantage of being able to function as a sealant or coating material, driven by which UV adhesives industry has witnessed a commendable growth trajectory since the last half a decade or so.

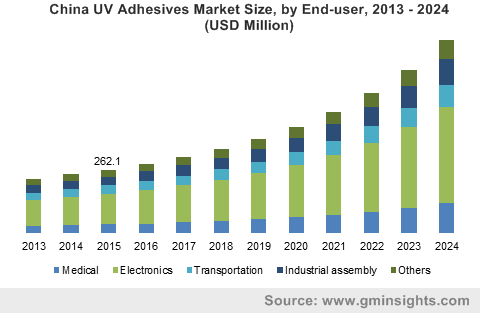

China UV Adhesives Market Size, by End-user, 2013 – 2024 (USD Million)

A brief overview of the application spectrum of UV adhesives market

The latest industrial scenario reflects that numerous operations, as on today, require products that have the capability to function in a harsh manufacturing environment. In this respect, modern industrial designs fraught with automation and UV adhesives are extremely compatible, as UV curing lamps are solid state, semiconductor-based devices enabling instant variable irradiance control of UV energy. This enables customers to heighten quality, reduce costs and speed up their processes. The industrial application of UV adhesives further extends to the manufacturing of wood/plastic coatings, solar panels, bottle processing, wind turbine repair, design prototyping via 3D printing and bottle processing. Undeniably, this has provided a huge spectrum of opportunities that UV adhesives market firms can harness in the years to come.

UV adhesives have made quite a mark across the medical device industry. That is to say, their virtually instantaneous curing procedure have made them highly popular in the sphere of medical device manufacturing, as rapid curing reduces material consumption and production cost. UV adhesives are preferred across this vertical owing to the range of materials they are compatible with, such as tinted and UV inhibited plastics.

Another factor that justifies the deployment of UV adhesives in the medical device manufacturing space is that besides being strong and flexible, they can withstand harsh medical sterilization techniques such as autoclaving. Elaborating further, when a medical device is autoclaved, adhesive will have to withstand a high-pressure atmosphere of more than 120 degree Celsius for nearly 30 minutes, with the procedure being repeated several times. Quite overtly, UV adhesives seem to be the most competent products that are strong enough to last the entire lifetime of the device. This has potentially widened the scope of these adhesives, leading to medical devices manufacturing emerging as a lucrative avenue for UV adhesives industry.

The electronics sector has also, in recent times, evolved as a profitable revenue ground for UV adhesives market. This is primarily due to the fact that the combination of high-energy UV adhesives provides increased productivity while offering the ability to cure heat sensitive materials. Given that they vastly improve the manufacturing processes of touch screens, micro speakers, mobile phones and hard disk drives, electronics industry players have whole-heartedly adopted UV adhesives. This has undoubtedly generated a profitable spectrum of opportunities for UV adhesives industry players from the electronics sector. Indeed, UV adhesives industry size from electronic applications was pegged at USD 332 million in 2016 and is expected to grow remarkably in the ensuing years.

Unveiling a region-wise growth graph of UV adhesives market

It is noteworthy to state that Asia Pacific would need a special mention as far as UV adhesives industry is concerned. This is primarily on account of the fact that the region houses a plethora of electronic component manufacturers spread across India, China, and Japan, striving to expand the scope of the regional electronics domain. China specifically, is renowned for the presence of touch panel and mobile phone manufacturers, pertaining to which the UV adhesives market share from China is likely to generate a valuation of $205 million revenue by 2024.

India on the other hand, boasts of programs such as ‘Make in India’ and ‘Digital India’ that have spurred the growth of the regional electronics sector. As per estimates, India UV adhesives industry size was pegged at $32 million in 2016 and is expected to contribute significantly toward the APAC market share over 2017-2024.

Speaking of the North American zone, it is prudent to mention that the U.S. accounted for a mammoth 75% of the regional UV adhesives market share in 2016. The massive shareholding can be essentially credited to the supportive regulations and criteria concerning volatile organic compounds. Powered by substantial investments in product innovation and the rapidly evolving medical equipment technology in the region, U.S. UV adhesives industry is likely to amass hefty returns by 2024. 2024.

Technological advancements in UV adhesive industry range from a dime to dozen, suitably helping this business space garner extensive remuneration. Say for instance, the UV LED lamp technology that can provide variable wavelength light ranging from 300 to 465 nm has created waves of anticipation in UV adhesives market. Aided by numerous innovative developments and a vastly diverse application landscape, UV adhesives industry size is expected to register a robust CAGR of 12% over 2017-2024.