Vacuum coating equipment market to witness strong growth prospects in Asia Pacific over 2016-2024, Rapid regional industrialization to drive the demand

Publisher : Fractovia | Published Date : 2017-05-05Request Sample

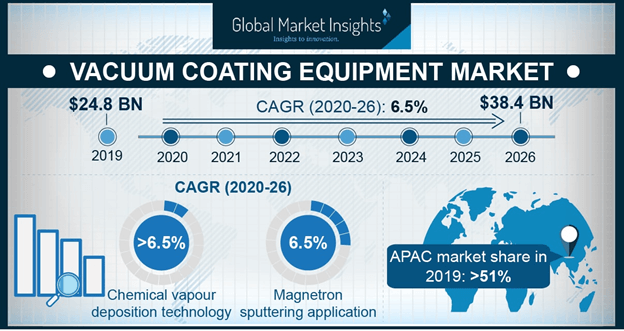

With the passage of time, vacuum coating equipment market has transited from an idea in a laboratory to one of the most highly commercialized industries globally. The distinguished equipment feature of vapor deposition technology is allowing the industry to capture the attention of a variety of sectors including automobile, electronics, energy, and power. An escalation in consumer demand for upgraded vehicles along with industrial automation is acting as a key propellant behind this industry’s rapid expansion. Vacuum coating not only improves the visual appearance of the vehicles but at the same time meet the functional criteria of durability and scratch resistance. With a wide range of applications across myriad sectors, vacuum coating equipment industry is set to attain a remarkable value in the years ahead. As per Global Market Insights, Inc., vacuum coating equipment market is poised to exceed a revenue of USD 47 billion by 2024 with a CAGR of 8 % over the coming seven years.”

Based on the various vacuum coating equipment available in the market, physical vapor deposition (PVD) vacuum coating equipment industry is witnessing a significant demand from industrial and automotive sectors. A continuous upsurge in passenger vehicle sales rate globally is expected to leave an influential impact on the overall vacuum coating equipment market. PVD coating day by day is replacing other conventional coatings such as chrome plating, painting, electroplating, etc. Longer shelf life, scratch resistant surface, bright colors that result in better performance of the engine, are some of the driving factors behind the industry’s significant expansion. PVD coating based vacuum coating equipment industry almost covered 39% of the overall market in 2015, and is anticipated to grow strikingly at an annual rate of 9% over the coming seven years. However, the complexity of the product may somewhat hinder the growth projection.

Europe Vacuum Coating Equipment Market, by product, 2013-2024 (USD Million)

The application spectrum of PVD coatings comprises microelectronics, cutting tools, medical equipment, solar power plants, and storage. Among these, the solar power plants are likely to exhibit a commendable demand for PVD vacuum coating equipment industry on account of the rising initiatives both by the private and government entities to set up solar power plants, particularly across the developing countries such as India and China. In addition, the other PVD coating application segments such as microelectronics and storage are anticipated to witness moderate gains over the coming years.

Combating the drawbacks of PVD coating such as complex functioning, Magnetron sputtering has emerged as the most promising product in the overall vacuum coating equipment industry. Despite having a comparatively lower market share than the other vacuum coating products, this segment is slated to witness an appreciable CAGR of 9% over the coming seven years. The growth can be attributed to the wide range of applications of this product such as electrical resistance films, corrosion-resistant films, magnetic films, opto storage devices, gas sensors, and metallizing for microelectronic circuits and chip carriers.

The evolving automotive industry is also offering huge business opportunities to the CVD vacuum coating equipment market. This equipment provides a uniform coating layer on the product and can be customized as per the product’s specifications. CVD vacuum coating equipment industry is also gaining a considerable share from its heavy deployment in integrated circuits, photovoltaics devices, metal-organic frameworks, polymerization, low-K dielectrics, and gas sensing.

U.S. being a leading participant in the renewable energy production, is estimated to remarkably contribute toward the global vacuum coating equipment market. Latin America is also likely to be a major ground for the vacuum coating equipment market growth in the coming years, attributed to the region being one of the largest commodities producers in the world.

Europe, led by Germany, will also contribute massively toward global vacuum coating equipment market growth. MEA, which held 2.3% of the vacuum coating equipment industry share in 2015, will also depict swift gains over the coming seven years.

Asia Pacific vacuum coating equipment market accounted for 50% of the global industry landscape in 2015. The region is projected to witness substantial gains in the years ahead with the rapid industrialization and expanding consumer electronic industry in this region.

Vacuum coating equipment industry is consolidated with major companies covering a chunk of the overall business landscape. Key players sharing this market space include Buhler Group, Kolzer SRL, BCI Blösch Group, Scientific Vacuum Systems Ltd., CVD Equipment Corporation, ULVAC, Inc., and Semicore Equipment, Inc.