Injection Molded Plastic Market to accrue maximum revenue via automotive applications over 2016-2023, APAC to be the major regional revenue contributor

Publisher : Fractovia | Published Date : 2017-05-24Request Sample

Injection Molded Plastic Market is anticipated to witness a high surge over the next few years, driven by strategic collaborations and mergers & acquisitions. For instance, IPL Inc., a leading producer of injection molded plastic items in North America, has announced the acquisition of Macro Plastics Inc., the largest global producer of rigid plastic bulk bins, for USD 150 million. Such growth strategies by injection molded plastic market players will favorably influence the business landscape. Worldwide plastic packaging sector, which was evaluated at USD 250 million in 2015, is anticipated to hit USD 425 million by 2023. The growth of this market will suitably impel injection molded plastic industry over the next few years. Growing product preference for high performance materials across the automotive sector is also expected to drive the market. According to Global Market Insights, Inc., “Injection Molded Plastic Industry is projected to grow at an annual rate of 5% over the coming six years.”

Government norms are anticipated to impact the growth of injection molded plastic market over the next few years. For instance, CAFÉ (Corporate Average Fuel Economy) has mandated directives to manufacture low fuel-emitting vehicles, which will propel the industry size. This product is characterized by resilience, corrosion resistance, and heat resistance, which will further push injection molded plastic market trends.

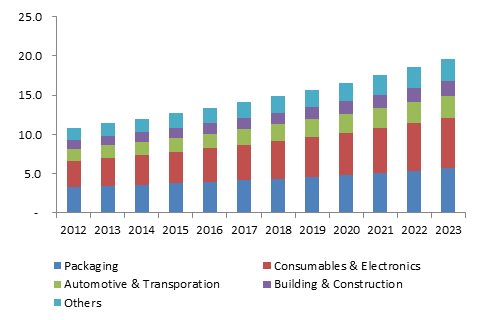

MEA Injection molded plastics market size, by application, 2012 - 2023 (USD Million)

Injection molded plastics find extensive applications across the automotive, packaging, building & construction, and consumables & electronics sectors. Injection molded plastic industry size from the consumables & electronics sector was worth USD 66 billion in 2015, and is estimated to register a noteworthy growth rate in the future. Rise in per capita income coupled with the heavy demand for laptops, refrigerators, food processors, mobiles, and microwaves will influence the business landscape.

Automotive & transportation applications are projected to grow at an annual rate of 5.7% over the period of 2016-2023, owing to high preference for these polymers in the production of automobile parts over the steel substrates. Injection molded plastic industry size from the construction sector is projected to grow notably over the span of few years, subject to the rampant use of plastics in buildings, pertaining to its cost-effective nature and ability to provide strength to walls, floors, windows, and doors.

Taking into consideration the topographical trends, Asia Pacific injection molded plastic industry, worth USD 76 billion in 2015, is projected to experience a massive surge over the span of few years. Heavy expenditure on construction activities coupled with beneficial government policies pertaining to FDI investments & subsidies will accelerate the regional growth. China, Japan, Indonesia, and India are predicted to be the key regional revenue pockets. In 2015, China, Japan, and India contributed to a major chunk of APAC construction spending by accounting for USD 1.63 trillion, USD 728 billion, and USD 412 billion respectively.

Injection molded plastic market in North America is slated to grow at an annual rate of 4.8% during the period from 2016 to 2023, driven by the escalating requirement for food & beverages packaging as a result of the rising popularity for processed food. The U.S. is projected to be a key regional revenue driver. Latin America injection molded plastic industry is forecast to record a CAGR of 4.6% over 2016-2023, owing to the ample availability of raw materials along with high FDI investments in Columbia and Brazil.

Raw materials such as polypropylene, polystyrene, acrylonitrile butadiene styrene, and high-density polyethylene are the key raw materials used in the production of injection molded plastics. Thriving HDPE (High Density Polyethylene) sector, which is expected to surpass a revenue margin of USD 88 billion by 2024, will contribute lucratively towards injection molded plastic market revenue over the years ahead.

Acrylonitrile butadiene styrene (ABS) injection molded plastic industry is predicted to record a CAGR of 5.2% during the period from 2016 to 2023, subject to the growing raw material usage for medical equipment in the healthcare sector. PP (Polypropylene) injection molded plastic industry, which was assessed at USD 72 billion in 2015, is forecast to grow substantially over the next few years, subject to the surging demand of the product in automotive, electrical & electronics, and packaging sectors.

Market players will try to expand their regional presence and enhance their product portfolio by developing innovative products. ExxonMobil Corporation, Huntsman Corporation, BASF SE, SABIC industries, The DOW Chemical Company, LyondellBasell Industries N.V., Eastman Chemical Company, INEOS Chemicals Company, Berry Global Incorporation, Magna International Incorporation, Beckton, Dickinson and Company, Newell Rubbermaid Incorporation, and International Automotive Components Group LLC are the key participants of injection molded plastic industry.